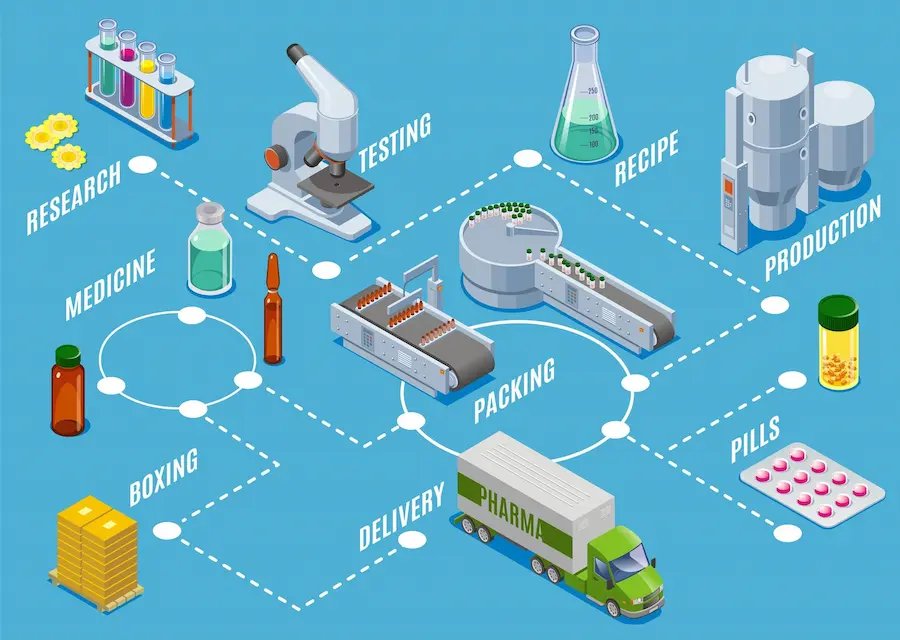

Team cohesion: the secret of success In today’s business world, a company’s success depends to a large extent on the ability of its teams to work together harmoniously and effectively. Team cohesion is essential to achieving objectives and stimulating innovation. Yet building and maintaining this unity is not always an easy task. In this article, we explore the key elements that promotecollective understanding, highlighting the importance of roles and responsibilities, the different phases of team building, and the imperative of having a clear vision and mission. Building a Team by Following the Steps To build a solid, high-performance team, it is important to understand the different stages in a group’s development. Bruce Wayne Tuckman, American psychologist and father of team-building , formalised the eponymous diagram which describes the four key stages through which teams pass: Step 1 : Forming At the beginning, team members get to know each other and try to understand their respective roles. This is a phase where expectations are often unclear, and where it is important for the leader to guide and clarify objectives and processes. Step 2 : Storming As members begin to work together, conflicts and differences of opinion may arise, particularly about how to achieve objectives. This is a necessary stage where members learn to negotiate and resolve conflicts constructively. Step 3 : Norming Once the initial tensions have been overcome, the team begins to find its rhythm and establish common working standards. Communication improves and members learn to collaborate effectively. This is a stage where the team begins to structure itself, with rules standardised through a common working framework. Step 4 : Performing In this final phase, the team is working to its full potential. The members are autonomous, motivated and work together coherently to achieve the objectives set. Cooperation is efficient. Tuckman’s principle (Click for zooming) DEFINE THE VISION AND MISSION A clear vision and mission are the glue that keeps a team together and motivated. The vision defines the team’s long-term goal, while the mission sets out its immediate purpose and core values. When all team members share and believe in this vision and mission, they are more likely to work together harmoniously and overcome obstacles with determination. GETTING TO KNOW EACH OTHER BETTER TO WORK BETTER TOGETHER This training course from our catalogue is dedicated to strengthening team cohesion by working on communication. Contact us Unite the group by clarifying roles and responsibilities Each team member brings unique expertise and specific skills. You will optimise the group’s performance by clearly defining each person’s roles and responsibilities. This strategy not only avoids overlap and conflict, but also ensures that each individual’s potential is fully exploited. By assigning clear missions, team members understand what is expected of them and can concentrate on accomplishing their specific tasks. The result is a feeling of trust and mutual respect between employees, because everyone knows that they can count on the others to fulfil their commitments. The Belbin model (Dr Meredith Belbin) establishes an inventory of roles according to 3 categories: Thinking roles (Designer, Taker, Expert) Action roles (Organiser, Promoter, Perfecter) Relationship roles (Coordinator, Supporter, Promoter) Each individual has a specific role within the team. By identifying and defining each person’s role, you can better understand your strengths and work together more effectively. Belbin’s model Team cohesion is an essential element of organisational success. By clearly defining roles and responsibilities, successfully navigating the Tuckman model of team building, and cultivating a shared vision and mission, teams can not only achieve their goals, but also thrive and innovate in a collaborative and motivating work environment. TEAM-BUILDING WORKSHOPS IN YOUR OFFICES! LUGAN CONSULTING can come to your company and organise fun, interactive team-building workshops. Book a session now. Contact us Frank LUGAN PHARMACEUTICAL QUALITY EXPERT Last posts Data Integrity : 8 steps to becoming compliant Pharmaceutical audit Team building : secret of success ANSM injunction : how to react ? The drug manufacturing process : from research to market launch

Team building : secret of success